Revolutionizing Business Operations with the Industrial Thermal Transfer Printer

In today’s fast-paced manufacturing and logistics environments, precision printing and durable labeling are essential for maintaining efficiency, compliance, and brand integrity. The industrial thermal transfer printer has become a cornerstone technology in this domain, offering unparalleled reliability and quality. As a leader in the printing services, electronics, and computer industries, OmegaBrand continues to pioneer solutions that empower businesses to achieve operational excellence. This comprehensive guide explores the transformative power of industrial thermal transfer printers and why they are indispensable for modern enterprise success.

What Is an Industrial Thermal Transfer Printer? An In-Depth Overview

An industrial thermal transfer printer is a high-end printing device designed specifically for heavy-duty, continuous operation in demanding industrial environments. Unlike desktop printers, these units are built to produce high-resolution, durable prints on a wide variety of materials including labels, tags, and flexible packaging. Their core technology involves transferring ink from a ribbon onto the substrate through heat, resulting in sharply defined graphics and text that withstand environmental stressors.

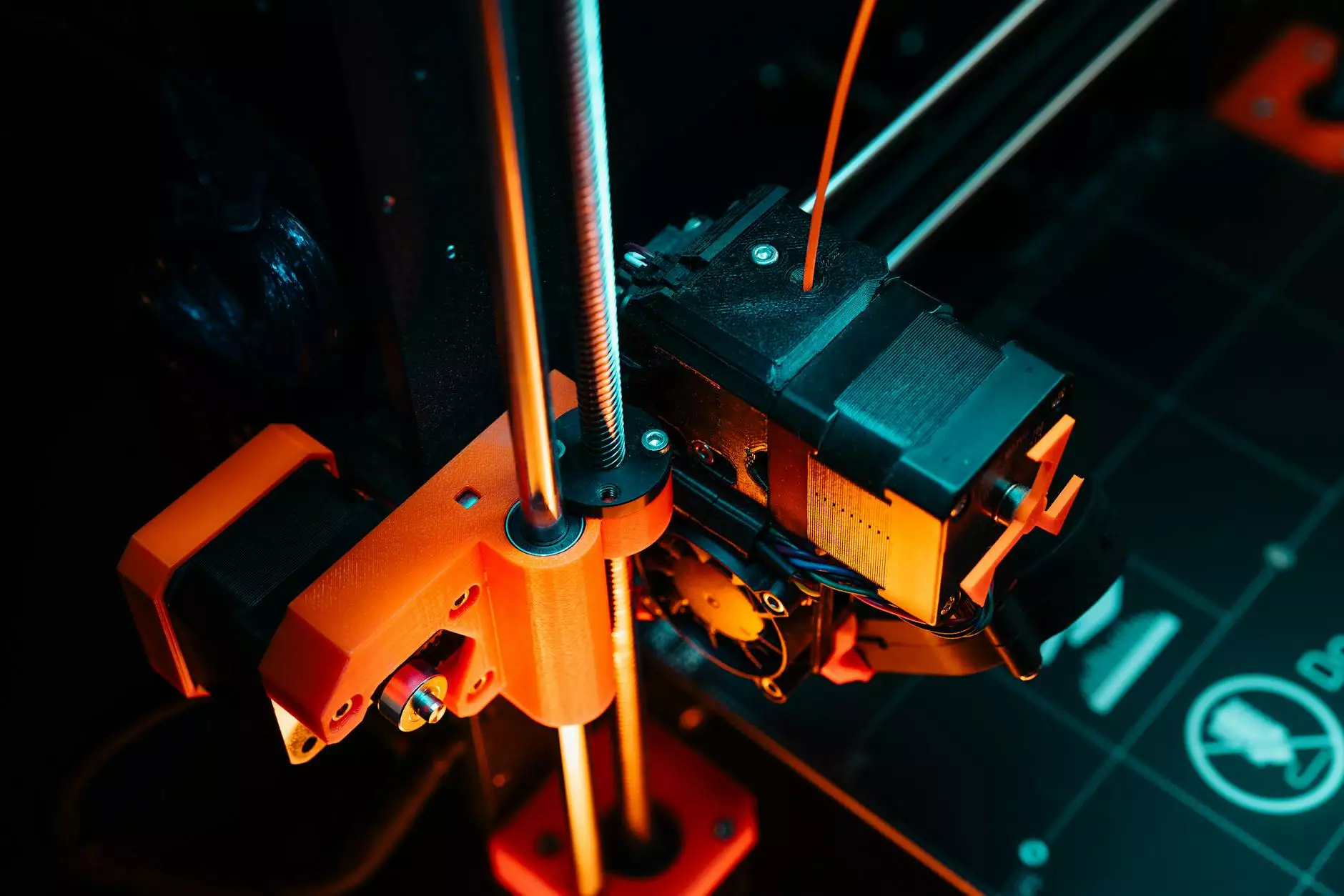

Key Components and Working Principle

- Print Head: The heart of the machine, generating precise heat to activate the ink on the ribbon.

- Ribbon: A resilient inked film that supplies the print medium.

- Media: The substrate, such as labels or packaging material, onto which printing occurs.

- Control System: Advanced electronics overseeing the heat application and media handling for optimal quality.

During operation, the thermal head applies heat selectively as the ribbon is fed through the system. The heat causes the ink on the ribbon to melt and transfer onto the substrate, creating durable prints with exceptional clarity and longevity. This technology allows for high-speed, high-volume printing with minimal waste and maximum accuracy.

Key Advantages of the Industrial Thermal Transfer Printer

1. Superior Durability and Resistance

The prints produced by industrial thermal transfer printer technology are highly resistant to exposure to moisture, chemicals, abrasion, and UV light. This makes them ideal for labeling in harsh environments, such as warehouses, factories, and logistics hubs, where labels must remain legible over long periods under challenging conditions.

2. Exceptional Print Quality and Precision

With advanced thermal head and ribbon technologies, these printers deliver crisp, clear images and text. Whether printing barcodes, serial numbers, or intricate graphics, the resolution capabilities ensure every detail is sharply defined, facilitating accurate scanning and tracking.

3. Flexibility in Media Compatibility

Designed to accommodate a broad spectrum of materials—including paper, polyester, polypropylene, and other synthetic substrates—these printers provide unmatched versatility. This adaptability allows businesses to tailor their labeling solutions to specific product or packaging requirements.

4. Long-Lasting Cost Efficiency

While the initial investment in industrial thermal transfer printers may be significant, their high throughput, low maintenance costs, and consumable efficiencies translate into long-term savings. Their robust components and reliable operation reduce downtime, ensuring continuous productivity.

5. Compliance and Traceability

In regulated industries such as electronics and pharmaceuticals, traceability is crucial. These printers support printing detailed, high-quality labels that meet stringent regulatory standards, facilitating compliance and audit readiness.

Application Domains and Industry-Specific Benefits

Printing Services: Elevating Customization and Volume

Professional printing services benefit immensely from industrial thermal transfer printers. Their ability to produce high-quality, durable labels at scale enables printing providers to fulfill large orders efficiently. Customization options, including variable data printing, advanced graphics, and serialized numbering, empower businesses to meet diverse client needs with speed and precision.

Electronics Industry: Ensuring Robust Labeling in Demanding Conditions

Electronics manufacturers rely on industrial thermal transfer printers for labeling circuit boards, components, and final products. The resilience of printed labels ensures they withstand environmental stressors such as heat, chemical exposure, and handling, protecting product integrity and facilitating warehouse management, quality control, and traceability.

Computers and IT Hardware: Accurate Identification and Branding

In the computer industry, high-resolution printing ensures the accurate marking of serial numbers, model identifiers, and branding elements on components and peripherals. The durability of these labels maintains their legibility during transportation, installation, and long-term use, thus reducing errors and enhancing brand reputation.

Technological Innovations Driving the Industrial Thermal Transfer Printer Sector

Recent advancements have propelled industrial thermal transfer printers into new realms of efficiency and functionality:

- High-Resolution Printheads: Offering resolutions up to 600 dpi for intricate graphics and tiny text requirements.

- Enhanced Ribbon Technologies: Development of ribbons with improved durability, environmental friendliness, and color options.

- Connectivity and Integration: Wireless, Ethernet, and USB interfaces facilitate seamless integration into production lines and inventory systems.

- Automation Capabilities: Features like automatic media handling, batch processing, and remote monitoring optimize throughput and reduce manual intervention.

Choosing the Right Industrial Thermal Transfer Printer for Your Business

Assess Your Business Needs

- Volume requirements—do you need high-speed, high-volume printing?

- Material compatibility—what substrates will you be printing on?

- Operational environment—are labels exposed to harsh conditions?

- Budget constraints—what is your investment capacity and expected ROI?

Key Features to Look For

- Robust build quality for longevity

- High-resolution print capabilities

- Versatile media compatibility

- Advanced connectivity options

- User-friendly interface and maintenance ease

Partner with a Trusted Manufacturer

Choosing a reputable supplier like OmegaBrand ensures access to reliable technical support, warranty services, and ongoing innovations that keep your business competitive.

Conclusion: Transforming Business Operations with the Industrial Thermal Transfer Printer

As industries evolve toward greater demands for durability, precision, and efficiency, the industrial thermal transfer printer stands out as an indispensable asset. Whether you operate in printing services, electronics manufacturing, or computer hardware, investing in this advanced technology can significantly enhance your productivity, product quality, and compliance adherence. OmegaBrand remains committed to providing top-tier solutions tailored to your specific needs, driving your success in a competitive marketplace.

Harness the power of state-of-the-art printing technology today and elevate your business operations to new heights with the industrial thermal transfer printer.